People may be aware of pipe relining, a new technique for maintaining drain pipes, but they may not understand how it might help you with your sewage line problems.

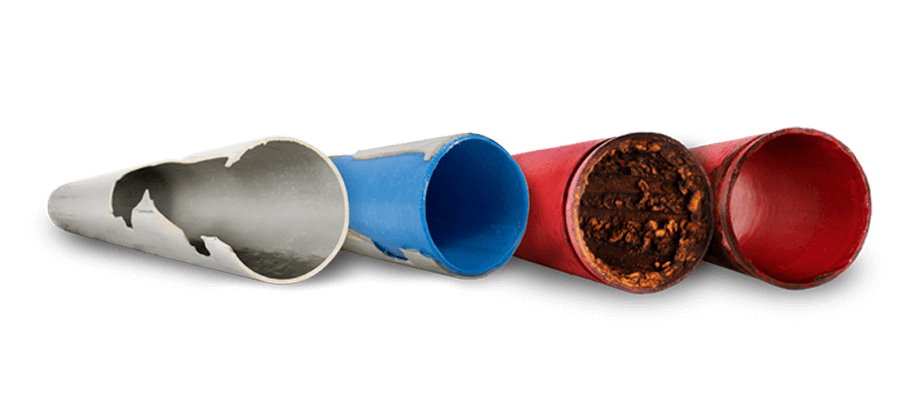

For a number of reasons, your drainage system may not be working. A broken pipe, years’ worth of accumulated debris or root intrusion from nearby plants and trees could all be contributing problems.

How pipe relining works Why should you choose The Relining Company‘s pipe relining process over conventional drain repair methods?

Relining of pipes

A recent development in technology allows for the repair of blocked, broken, or fractured drainage pipelines.

The fact that everything is done above ground distinguishes pipe relining from standard pipe maintenance the most. As a result, there won’t be much excavating and your home won’t be harmed.

The new pipe that is formed within the host pipe will also be stronger and eliminate any problems with the pipe in the future including root incursion, fracturing, pipe breakage, and misaligned joints. Owners of homes and businesses may relax knowing that their drains won’t jam up again any time soon.

Relining Procedure

The same methods are used in pipe relining to solve various drain issues. A qualified expert will first inspect your system using CCTV technology. Real-time photography will show any damaged pipes, displacement, outdated pipe components, or misplaced pieces.

The inner pipe is next prepared for the lining by clearing your drains of decades’ worth of scale, dirt, and obstructions using the hydro-jetting technique.

Your custom-made bladder and liner are created by professionals and inserted into your drainage system. Using CCTV technology, it is ensured that the liner will span the fractured portion of your pipes.

The liner is inflated by compressed air, which causes the distinctive epoxy glue to cling to the drain’s interior bore. After a few hours, the glue will harden, creating a new pipe inside the old one. After the balloon is deflated and removed, a stronger framework is left behind, enabling the drain to perform properly once more.

A final CCTV inspection of the drain is performed by experts to ensure that the task was completed properly. Within a few hours, you’ll have a drain that is fully operational and durable.

Pipe relining versus conventional drain repair

Pipe relining exceeds conventional pipe restoration as a simple yet efficient method of pipe maintenance. An internal material that is smooth and seamless and many times more durable than PVC makes up the pipe.

Relining eliminates the need for excavations and pipe maintenance, as well as the associated costs of landscape restoration. It is a non-destructive method of drain repair that prevents trench excavation, traffic congestion, structure damage, and other problems associated with standard drain restorations.

Conclusion:- The new jointless structure has a number of benefits of its own. Calcification will cease to exist since debris won’t adhere to the inner bore. It can even enhance total flow and capacity. It can withstand greater pressure than conventional drain materials. When you need your drain lines repaired quickly and effectively, it is unquestionably the better alternative.